Electrolytic Sensor Method inc|Industrial and Automotive Sensors : factories Industries - Industrial and Automotive Sensors | Methode Sensor Technologies Resultado da 26. 701.5K. Se inscrever. Vídeos porno da Larissa Manoela nua. Filtros. HD. Mais Recentes. Full videos. 01:25. Larissa manoela. 40.7K views. 04:12. .

{plog:ftitle_list}

O Senhor das Armas. Direção: Andrew Niccol. Elenco: Nicolas Cage , Ethan Hawke , Jared Leto. Título original Lord of War. Usuários. 4,2 1914 notas, 28 críticas. Meus .

Methode Sensor Technologies, a Methode Electronics company, is focused on the design and development of its core sensor solutions for a global Automotive and Industrial client base. Our team of sensor experts strives to offer the most comprehensive knowledge and support to our .Technologies - Industrial and Automotive Sensors | Methode Sensor TechnologiesUS: Phone: 248-415-2416 Address: Methode Electronics Inc. 25650 West 11 .Methode Sensor Technologies creates innovative industrial and automotive .

Industries - Industrial and Automotive Sensors | Methode Sensor TechnologiesCapabilities - Industrial and Automotive Sensors | Methode Sensor Technologies

Locations - Industrial and Automotive Sensors | Methode Sensor TechnologiesThe dual-channel sensor outputs respond in a differential manner, while a built in .

maven package skip test

Magnetoelastic Sensors - Industrial and Automotive Sensors | Methode Sensor .

Capacitive & Field Effect Sensors - Industrial and Automotive Sensors | .Automotive - Industrial and Automotive Sensors | Methode Sensor TechnologiesWe design, engineer, and produce mechatronic products for OEMs utilizing our broad range of technologies for user interface, LED lighting system, power distribution and sensor applications. Methode Electronics, Inc. (NYSE: MEI) .

Methode pioneers and begins manufacturing “complex insert-molded” Leadframes for power and signal distribution within automotive transmissions; .

Solutions & Technologies. Methode’s design, quality, manufacturing and validation engineers collaborate with our customers in the areas of user interface, human machine interfaces, LED .Methode Sensor Technologies creates innovative sensing solutions and develops new technologies to suit our clients’ needs, including custom-designed and engineered products.Methode’s primary sensor technologies include electro-mechanical, eddy current, and magneto-elastic in applications such as pedal box, ignition systems, transmission, and steering.

Methode Electronics (NYSE: MEI [3][4]) is an American multinational company headquartered in Chicago, Illinois, with engineering, manufacturing and sales operations in more than 35 .We design, engineer, and produce mechatronic products for OEMs utilizing our broad range of technologies for user interface, LED lighting system, power distribution and sensor applications.Electrolytic sensor method, together with dynamic relative humidity testing method and infrared testing method, belongs to sensor method water vapor permeability testing. It was .

Place you in control of the measurement technology and supply chain for your products. Phone: +44 (0)1223 694158. Sensor methods offer inductive sensor designs, inductive motor encoders and sensor engineering design .

ISO 15106-3:2003 specifies an instrumental method for determining the water vapour transmission rate of plastic film, plastic sheeting and multi-layer structures including plastics, using an electrolytic detection sensor. NOTE The method provides rapid measurement over a wide range of water vapour transmission rates.Methode Sensor Technologies creates innovative sensing solutions and develops new technologies to suit our clients’ needs. Home; Company. Locations; Technologies. . or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

ISO 15106-3 - Plastics -- Film and sheeting -- Determination of water vapour transmission rate -- Part 3: Electrolytic detection sensor method C330H Water Vapor Transmission Rate Tester C330H, also moisture vapour transmission rate tester, is designed and manufactured based on the electrolytic sensor method and conforms to the requirements of .METHODS OF ACCURATELY MEASURING CAPACITIVE RH SENSORS Kevin Bull Veriteq Instruments Inc., Richmond BC, Canada Abstract: The operation of Capacitive RH Sensors has been well described in the literature and is generally well understood. The electronic circuits used to measure these Sensors, on the other hand, have not been well described.

Abstract: Electrolytic conductivity (EC) sensors are widely used in diverse industries, including: pharmaceuticals, food, power, manufacturing, and environmental monitoring. This article presents an overview and analysis of EC sensors used in these industries from the lowest to the highest range of conductivities and in applications, where there are strong . This work addresses the development of practical models for understanding and quantifying the signal response of electrolytic sensors that compensate for confounding effects on the sensor response, and address other issues that affect the usability of low-cost sensors, such as sensor drift and inter-sensor variability. Traditional air quality monitoring relies on .

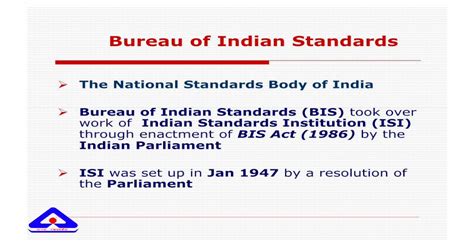

Summary on the Enactment of the National Standard on

We studied a Mach–Zehnder Interferometer (MZI)-based electrolytic sensor on a silicon-on-insulator (SOI) platform. First, the Si waveguide, integrated with the dielectric layer (SiO2) and operating under varying pH, is designed using commercial software Nextnano. The impact of the band bending in the SiO2 integrated with the Si waveguide is presented. .DOI: 10.3390/s151027283 Corpus ID: 14684978; Quantification Method for Electrolytic Sensors in Long-Term Monitoring of Ambient Air Quality @article{Masson2015QuantificationMF, title={Quantification Method for Electrolytic Sensors in Long-Term Monitoring of Ambient Air Quality}, author={Nicholas Masson and Ricardo Piedrahita and Michael Hannigan}, . The detection range of the bio-electrolytic sensor was up to 100 mM which is much higher than that of MFC-based sensor (Kaur et al., 2013) and almost at the same level as that of the MDC-based sensor reported previously (Jin et al., 2016). It should be noted that the response time (i.e., 1 h) achieved in this study was much shorter compared to .Electrolytic detection sensor method 1 Scope This part of ISO 15106 specifies an instrumental method for determining the water vapour transmission rate of plastic film, plastic sheeting and multi-layer structures including plastics, using an electrolytic detection sensor.

maven package recursive test loop

The Fredericks Company is an industry leader in electrolytic tilt sensors for an innovative and proven method of measuring anywhere from ±60° down to ±0.5° with high accuracy ranging from ±0.1° (±360 arcseconds) to ±0.0003° (or ±1 arcsecond).Generally, as the range of a tilt sensor decreases, the accuracy increases, which can be seen by looking at our tilt measurement .

Electronic noses (or, in short, eNoses) are analytic devices that play a constantly growing role as general purpose detectors of vapor chemicals [1]. The main component of an eNose is an array of non-specific sensors, i.e., sensors that interact with a broad range of chemicals with varying strengths.Industry-Leading Electrolytic Tilt Sensors. The Fredericks Company is the leading manufacturer of precision tilt sensors and angle measurement devices. Tilt sensors measure an angular position with reference to gravity and are used in a wide variety of applications from laser levels to seismic monitoring to medical devices. The Fredericks .Electrolytic sensor method, together with dynamic relative humidity testing method and infrared testing method, belongs to sensor method water vapor permeability testing. It was gradually introduced since 1970. Requiring the same test environment as that of water method, electrolytic sensor method is distinguished for its rapid test speed, high .

Solutions & Technologies

Electronic Sensors, Inc. (ESI) "Level Devil" American-made tank monitors and tank-monitoring systems monitor bulk fluid tank levels of most fluids -- industrial chemicals, cyrogenics, fuels .

Electrochemical Functions. Mikio Miyake, in Carbon Alloys, 2003. 4.3 Sensor. An electrochemical sensor is a device that quantitatively detects a particular chemical species as an oxidation or reduction current [3, 25, 26].An electrochemical sensor has advantages such as simple measurement procedure, short response time, and sufficient sensitivity and selectivity.

Solutions & Technologies. Methode’s design, quality, manufacturing and validation engineers collaborate with our customers in the areas of user interface, human machine interfaces, LED lighting, sensors, power distribution, and digital information over copper.In Stock TKE Trace Moisture Cell. This new P₂O₅ electrolytic cell developed by TKE is a cost saving and versatile solution for the measurement of water concentrations in gases down to 1 ppmV.. The cell can be opened, therefore the user can easily clean and regenerate it many times before a replacement becomes necessary.. The cell is also suitable for permanent installation .A sensor-less current waveform prediction method is proposed. Popular current mode control with the switch current signal is used. Repetitive sampling on the switch current allows capacitors current waveforms prediction without any current sensor at capacitor nodes. Together with the voltage waveform acquired, the ESR value can be calculated.

IR Sensors or Infrared Sensor are light based sensor that are used in various applications like Proximity and Object Detection. IR Sensors are used as proximity sensors in almost all mobile phones. There are two types of Infrared or IR Sensors: Transmissive Type and Reflective Type.A method is presented that permits hygrometry with established electrolytic cell technology to achieve single-digit parts-per-billion (ppb) levels. This technology is based on Faraday’s law and considered an absolute method, which is a significant .

A deep feature mining method of electronic nose sensor data for identifying beer olfactory information. J. Food Eng., 263 (2019), pp. 437-445. View PDF View article View in Scopus Google Scholar [26] D.R. Wijaya, R. Sarno, E. Zulaika. DWTLSTM for electronic nose signal processing in beef quality monitoring.the action and counter electrodes, the sensor determines the gas concentration. 3. eatures (of the sensor Si (2S sensor) as an example) utput characteristics The gas concentration is proportional to the current value. The sensor outputs the current value without any change and the gas concentration is, therefore, proportional to the sensor output. A thin film platinum electrode-based electrolytic moisture sensor for the measurement of lower concentrations of moisture in gas streams with flow rates lesser than 5ml/min was designed. A thin-film electrochemical sensor electrode capable of electrolytic conductivity, cyclic voltammetry, and temperature measurements of electrolyte solutions has been fabricated and characterized. The electrode fabrication and calibration is detailed, showing accuracies of $$\pm$$ ± 6 % for electrolytic conductivity measurements over the range of .

WHAT YOU GET: Model PPM1 Diffusion Cell Trace Moisture Analyzer comes complete with Phosphorous Pentoxide (P2O5) and an Electrolytic Sensor with an operating range from 0.1 to 1250 PPMv (dew point range: -20 ° C to -95 ° C). Standard sensor assembly is mounted remotely from the analyzer module and features a flow through 316SS sample chamber with ¼” .Insent's e-Tongue taste sensor is a biomimetic technology inspired by the structure and function of biological membranes. A single biological taste receptor can capture the same taste attribute, such as bitterness, for multiple chemicals. . (electronic ‘tongue’) taste sensor in 1993, more than 600 business customers worldwide now use this .

Sensor Technology

Atsushi Koyama 1978 Born in Tokyo, Japan 2002 B.F.A., Tama Art University, Tokyo, Japan 2008 B.Sc. Mathematics, Tokyo University of Science, Tokyo, Japan Award 2020 Grand Prize, "Creation & Culture 2020", ORIGINALMIND INC. Nagano, Japan Solo exhibition 2019 "The Reverse Rotation", Frantic Gallery, Tokyo, Japan

Electrolytic Sensor Method inc|Industrial and Automotive Sensors